#Design#

#Research#

The green façade is a recently developed technology, which not only has a decorative effect, but also plays an important role in absorbing dust, improving air quality and reducing the heat island effect. 3d-printed clay, or Liquid Deposition Modeling (LDM) is also a production method that has emerged in recent years, with a profound impact on the realization of digital design and individualized production, architecture and building construction. This paper discusses the current development of green façade and the design of the green wall module using 3D printing clay technology. At the same time, the possibility and effectiveness of combining 3D printed clay with green façade was demonstrated. And this paper also contains a design practice.

Introduction

In the past few decades, the world has experienced rapid urbanization, corresponding increase in residential densification, especially in developing countries. Urbanization will increase the hard-paved ground, which will inevitably bring about the heat island effect. In order to suppress the urban heat island effect, many concepts have been proposed, including building greening. The earliest practice is roof planting.

Starting in the 1970s, roof greening technology began to be practiced and has become a relatively mature industry so far. According to the Dachverband Deutscher Gartenfreunde e.V., an estimated 12 to 14 million m2 of roof area are greened in Germany. In many architectural designs, green roofs have become a must. However, people are not just satisfied with greening the roof. In order to achieve higher green coverage, the concept of green facade was introduced.

The “green façade” or the “green wall” or “vegetated facade” is defined as a system in which plants grow on a vertical surface such as a building façade in a controlled fashion and with regularly maintenance. Normally the green façade system consisted following elements: plant module, support structure, substrate, plants and irrigation system.

In this article, we briefly discussed the function and significance of the green wall and the specific technical details of the related design, including the impact on the city and the significance of mitigating the urban heat island effect. We also summarized the current development status of green walls and the specific technical details of wall design, including plant selection and plant cultivation methods. Finally, we also had some discussions about clay 3D printing. In this article, several related cases are studied and summarized, in order to have a complete consideration from function, form to realization method.

Environmental advantages of green walls

The urban heat island effect will lead to higher temperatures inside the city, which in turn will affect the indoor temperature of housing or other buildings. This process is facilitated by higher urbanization, which leads to deterioration of the urban habitat and quality of life. For cities at this stage, the key to mitigating the heat island effect is to retrofit existing buildings. At a higher level, this technology is also positive for the challenges posed by climate change. Walls and roofs are directly exposed to sunlight, which is the most direct factor affecting building temperatures. Therefore, applying vegetation on walls and roofs is one of the methods.

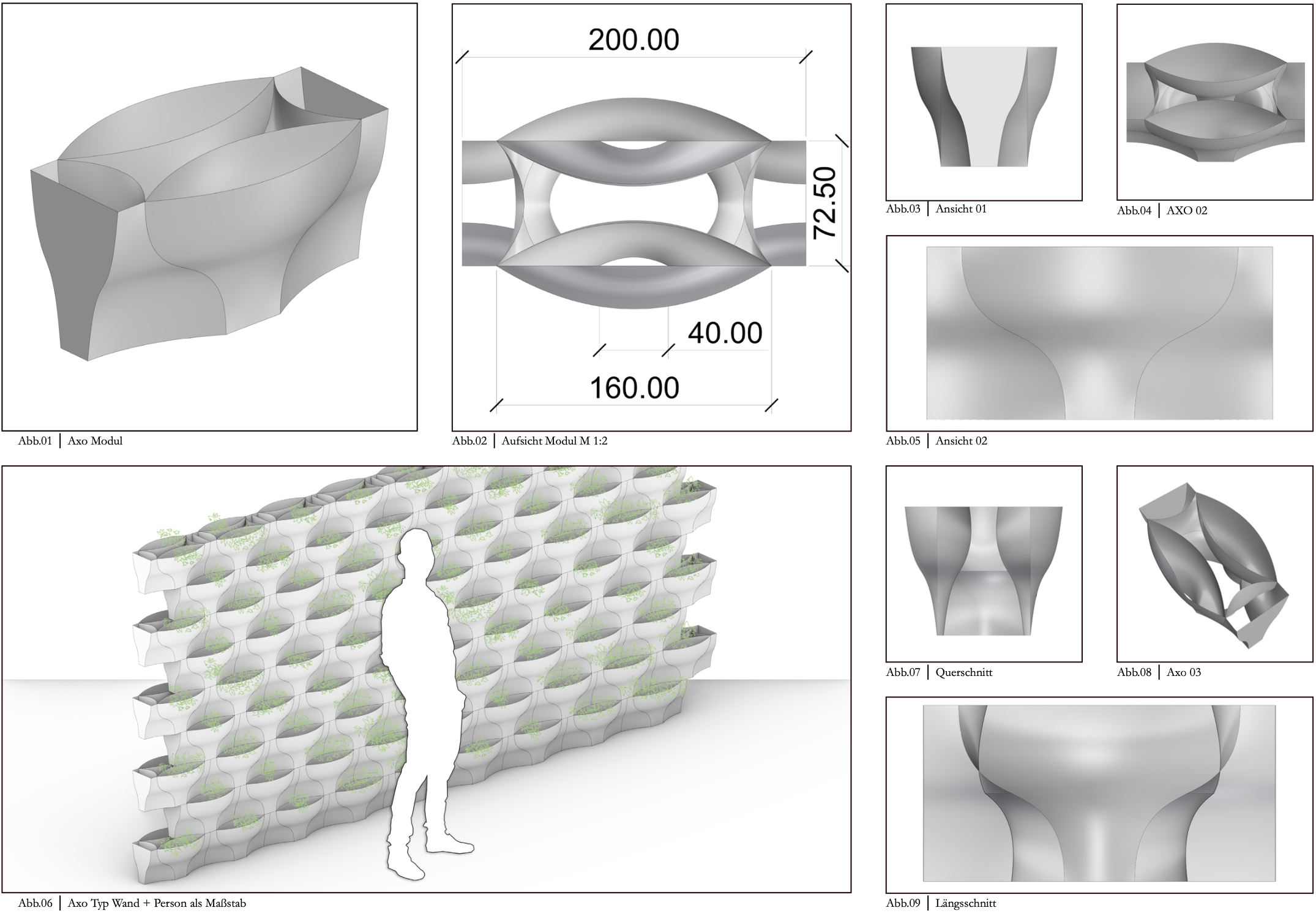

In terms of roof improvement and design, roofs with vegetation cover can effectively reduce indoor temperatures due to the reduced thermal conductivity compared to conventional roofs. However, due to the area of exterior walls is larger than the area of roofs, the application of vegetation on roofs alone is not enough for many buildings in urban interiors. Therefore, green walls are particularly important in regulating indoor temperatures. On the other hand, the treatment of walls is also beneficial due to the now mature modular process. Modularity has a low-cost feature, and it is easy to mass produce and renovate. Therefore, through the research and design of modular green walls, one can realize the renovation of a large number of existing buildings in a relatively short period of time.

Introduction of using 3d printed clay clay as a planting wall module

Clay is a natural building material, also a traditional building material in many parts of the world. Clay can be sourced locally, is inexpensive, and has the advantages of fireproofing, heat insulation, and moisture absorption. The most common application of clay is sintered clay into blocks or tiles. Traditional solid blocks are heavy and consume a lot of materials, today mainly use light weight and high strength hollow block materials. Walls using clay blocks often present a homogeneous feel often with a sense of craft aesthetics. Also the color of pottery can vary a lot, depending on the mineral content of the clay. Of course, clay can also be artificially tinted.

Pottery made of clay is still a very popular pot material for gardeners because of its physical properties that are well suited to plant root growth. The porosity of pottery ensures the circulation of air and water, which prevents the growth of root rot and other fungal diseases. Pottery does not require too high a temperature to sinter, typically 600-1000 degrees Celsius.

Clay is fluid at high water content, which allows it to be extruded by the 3d printing nozzel for printing. 3d printing and digital design give clay materials higher morphological possibilities.

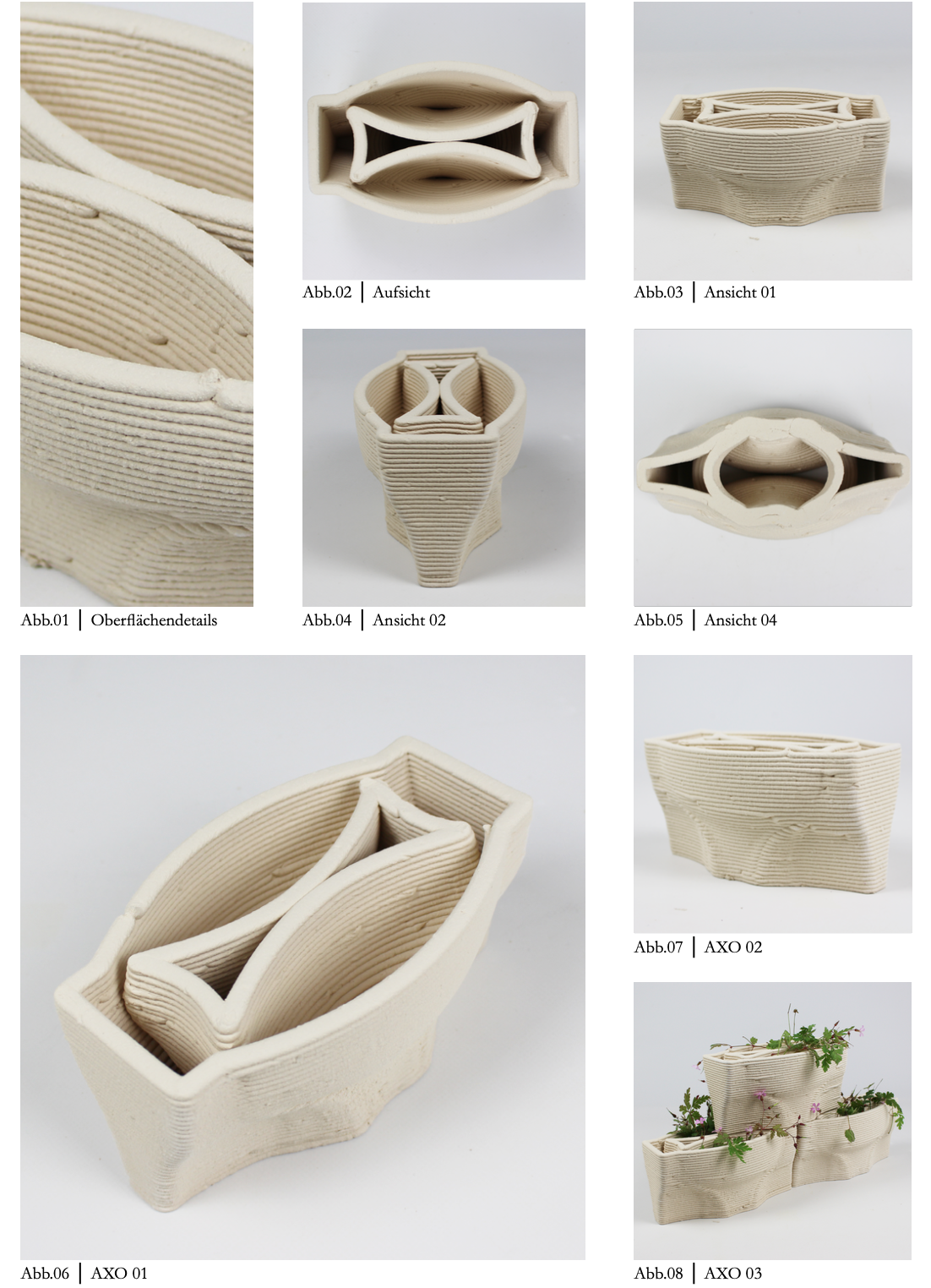

Design

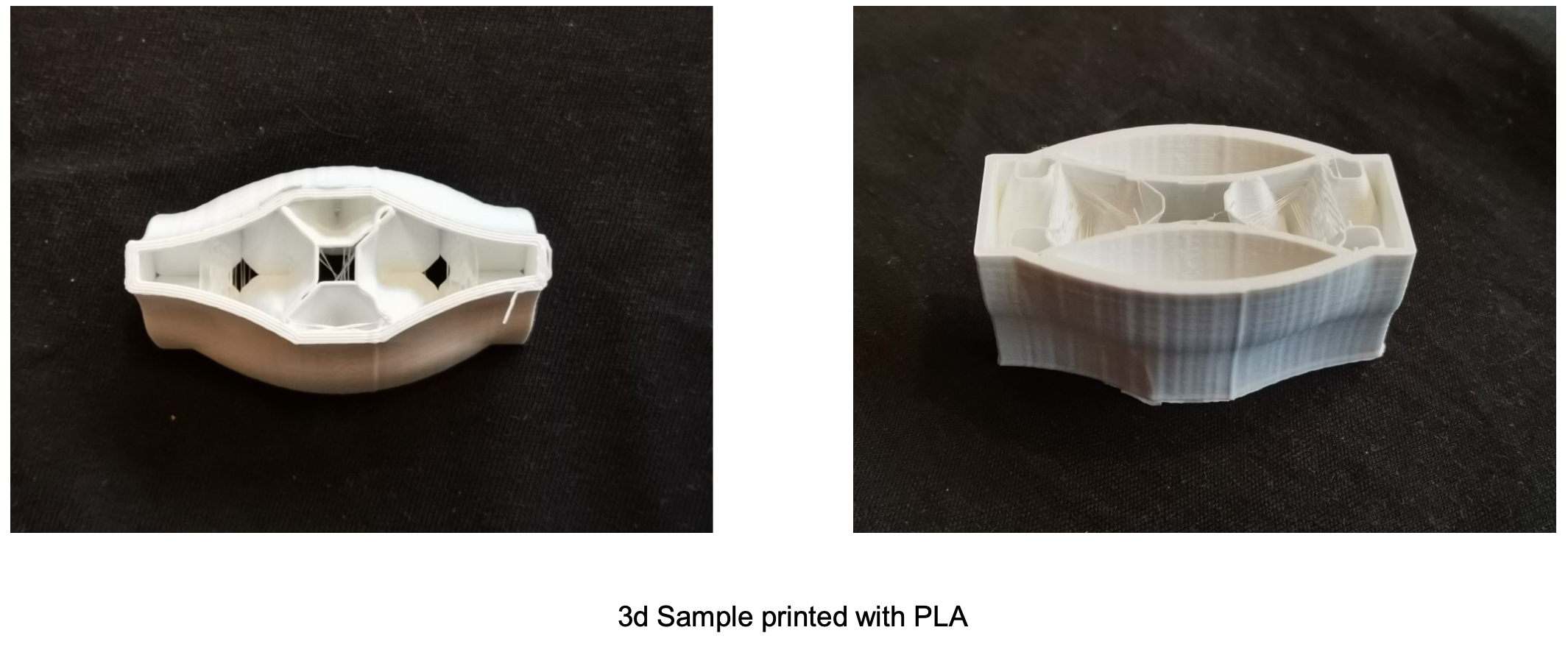

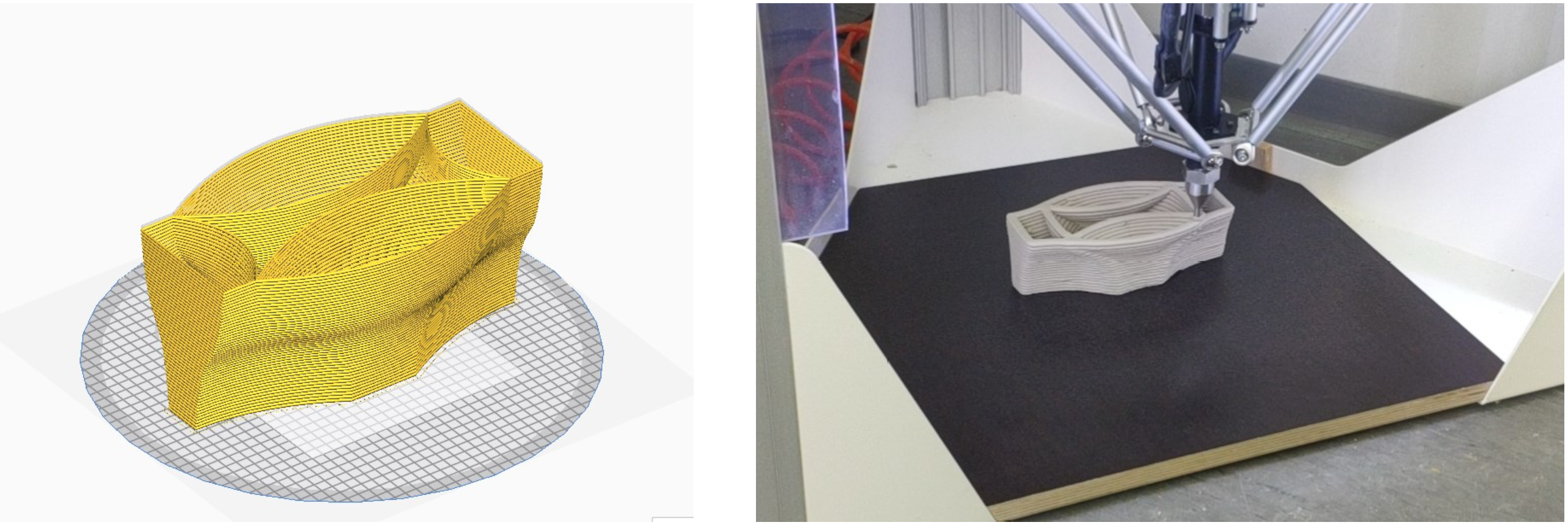

Based on the previous study, we experimented with a clay 3D printing module design. After a comprehensive study of the properties of clay and several manual experiments, we used Rhino to model the module. The form is formed by connecting several surfaces, and the interlocking arrangement of these surfaces gives the whole façade a sense of flow. We also developed a parametric generation script based on Grasshopper, which allows the form to be adapted to any surface.

We completed the machining process using the Cura platform and the Delta clay 3D printer. The whole model consists of eight surfaces. The exterior includes two surfaces and two planes on both sides, and the interior has two surfaces that play a structural role in addition to the two surfaces that correspond to the exterior surfaces, and the design of these two surfaces also makes the whole interior form a closed form for the printer to make continuous printing. Between the inner and outer surfaces is an implantation tank. There are drainage holes at the bottom of the implantation tank, so that water can be drained downward through the cavity inside the module.

In this practice, we tried the whole process from design to processing of the green wall module based on clay material and 3D printing method. The final module shows a freer form and ensures the basic function of the green wall to a large extent. We believe that this practice can better demonstrate the potential of clay materials and 3D printing.

Conclusion and discussion

This paper briefly explains the function and significance of the green wall and the specific technical details of the related design. Within this logic, the article conducts a study of the technical requirements of green walls and identifies a set of requirements that should be met in the design of a green wall system. This includes functional requirements, substrate, plants, materials and process requirements. Two specific case studies are also studied and discussed. The green wall using clay materials and 3D printing methods has several advantages:

- A freer form design can be achieved due to the clay and properties and technical support of 3D printing.

- The clay materials generally used nowadays are light in weight and strong enough to meet the technical requirements of green walls.

- Clay is a traditional potting material, suitable for plant growth.

- 3D printing technology ensures a modular production process.

Through the discussion in this paper, we conclude that 3D printed clay has great potential in the technical field of green walls.

Collaborators: Shuai Fu, Care, support: Christina Klug.